The Future of Armored Cable: Stainless Steel Innovations

The Evolution of Armored Cable

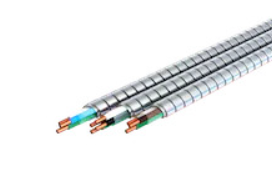

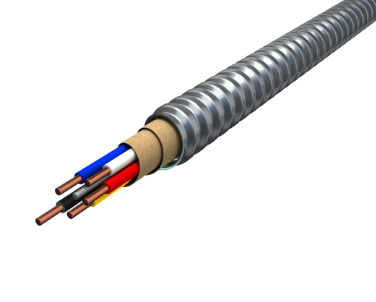

Armored cable has experienced significant advancements in recent years, revolutionizing the way cables are designed and implemented. One notable innovation that is shaping the future of armored cable is the introduction of stainless steel construction. This new approach offers enhanced durability and resistance to environmental factors, making it an ideal choice for various applications. Unlike traditional cables, armored cables feature a protective layer that provides additional reinforcement and shielding against physical damage, moisture, temperature fluctuations, and electromagnetic interference (EMI). These advancements have led to the development of more reliable and robust armored cables that can withstand challenging conditions in industries such as construction, manufacturing, telecommunications, and power distribution.

Unveiling Stainless Steel Innovations

Stainless steel armored cable represents a significant advancement in cable technology, offering numerous benefits and applications across various industries. This section will explore the advancements in stainless steel armored cable and its versatile applications.

Advancements in Stainless Steel Armored Cable

Stainless steel armored cable is a type of cable that features a stainless steel construction, providing exceptional durability and protection. The key features and benefits of this innovative design include:

Enhanced Durability: Stainless steel construction offers superior resistance to corrosion, moisture, chemicals, and physical damage. This makes it ideal for harsh environments or areas prone to wear and tear.

Environmental Resistance: Stainless steel armored cables are designed to withstand extreme temperatures, making them suitable for both indoor and outdoor applications.

Electromagnetic Interference (EMI) Shielding: The metal-clad nature of stainless steel reinforced cables provides excellent EMI shielding capabilities, ensuring reliable signal transmission even in electromagnetic-heavy environments.

When compared to other types of armored cables such as metal-clad cables or wire-armored cables, stainless steel armored cables offer distinct advantages in terms of durability, flexibility, and performance.

Applications of Stainless Steel Armored Cable

Stainless steel armored cable finds versatile applications across various industries due to its robust construction and reliability. Some common applications include:

Industrial Settings: Stainless steel armored cables are widely used in industrial settings where protection against harsh conditions is crucial. They are commonly employed in manufacturing plants, oil refineries, chemical facilities, and mining operations.

Commercial Buildings: In commercial buildings such as offices, hospitals, schools, and shopping centers, stainless steel armored cables provide a safe and reliable solution for electrical wiring advancements.

Residential Installations: Homeowners can benefit from the use of stainless steel armored cables for added safety in areas where wear-and-tear or rodent damage may be a concern.

Real-world case studies showcasing successful implementations of stainless steel armored cables will be discussed later in this blog, providing valuable insights into their practical applications. Additionally, the continuous advancements in stainless steel cable technology are expected to drive future developments and emerging trends in the industry.

Versatile Applications and Construction

Armored cable finds diverse applications in various industries, both for industrial and commercial/residential purposes. This section will explore the different applications of armored cable and important considerations in its construction and design.

Diverse Applications of Armored Cable

Industrial Applications: Armored cable is widely used in industrial settings due to its ability to withstand harsh conditions. It is commonly employed in power plants, manufacturing facilities, refineries, and chemical plants. These environments often require cables that can resist physical damage, moisture, chemicals, and extreme temperatures.

Commercial and Residential Applications: Armored cable is also utilized in commercial buildings such as offices, hospitals, schools, and shopping centers. In these settings, it provides a reliable solution for electrical wiring needs while ensuring safety and durability. Additionally, armored cable is increasingly being used in residential installations where protection against wear-and-tear or rodent damage is required.

Benefits of Using Armored Cable: The use of armored cable offers several advantages across different environments. These include enhanced protection against physical damage, resistance to environmental factors like moisture and temperature fluctuations, improved safety due to reduced risk of electrical fires or short circuits, and better longevity compared to non-armored cables.

Construction and Design Considerations

When selecting armored cable for a specific application, certain factors should be considered:

Technical Specifications: Understanding the technical specifications of armored cable construction is crucial. This includes aspects such as conductor material (copper or aluminum), insulation type (PVC or XLPE), armor material (galvanized steel or aluminum), and overall design standards (such as NEC or IEC).

Structural Requirements: Consideration should be given to the structural requirements of the installation site. This includes evaluating factors like bending radius limitations, impact resistance needs, flexibility requirements for easy installation in tight spaces or conduit systems.

Installation Best Practices: Proper installation techniques are essential for maximizing the performance and longevity of armored cable. This includes ensuring correct cable routing, appropriate grounding, and following industry standards and regulations.

Maintenance Considerations: Regular inspection and preventive maintenance are important to identify any potential issues with armored cable installations. This helps in detecting signs of wear, damage, or degradation early on, allowing for timely repairs or replacements.

By carefully considering these construction and design aspects, engineers and technicians can ensure the successful implementation of armored cable systems in various applications.

Engineering and Technical Advantages

Armored cable offers several technical advantages that make it a preferred choice in various applications. This section will explore the technical benefits of armored cable and the engineering considerations associated with its implementation.

Technical Advantages of Armored Cable

Enhanced Durability: Armored cable is designed to provide superior durability and protection against physical damage. The armor layer acts as a shield, safeguarding the internal conductors from impact, abrasion, and other external forces.

Resistance to Environmental Factors: Armored cable exhibits excellent resistance to environmental factors such as moisture and temperature fluctuations. This makes it suitable for installations in both indoor and outdoor environments, ensuring reliable performance even in challenging conditions.

Electromagnetic Interference (EMI) Shielding: The metal armor of armored cable provides effective shielding against electromagnetic interference (EMI). This helps prevent signal degradation or disruption caused by nearby electrical equipment or other sources of electromagnetic radiation.

Engineering Considerations for Armored Cable

Compliance with Industry Standards: When selecting and installing armored cable, it is essential to ensure compliance with relevant industry standards and regulations. Adhering to these guidelines ensures the safety, reliability, and compatibility of the cable system within its intended application.

Safety Features and Risk Mitigation Strategies: Armored cable often incorporates additional safety features such as fire-resistant insulation or grounding capabilities. These features help mitigate risks associated with electrical faults, reducing the likelihood of accidents or damage.

Future Innovations and Advancements: The field of armored cable technology continues to evolve, with ongoing research leading to future innovations. These advancements may include improved materials, enhanced performance characteristics, or new design approaches aimed at further enhancing the durability, flexibility, and overall functionality of armored cables.

By leveraging the technical advantages offered by armored cables while considering important engineering considerations, professionals can confidently implement robust and reliable electrical systems across various industries.

Best Practices for Installation and Maintenance

Proper installation and maintenance of armored cable are essential to ensure its optimal performance and longevity. This section will provide guidelines for the installation process as well as tips for ongoing maintenance and troubleshooting.

Installation Guidelines for Armored Cable

Proper Handling and Storage: When handling armored cable, it is important to avoid excessive bending or twisting that could damage the internal conductors. Additionally, cables should be stored in a dry, clean environment to prevent moisture or debris from affecting their integrity.

Installation Techniques and Considerations: Following industry standards and recommended practices is crucial during the installation process. This includes using appropriate tools, connectors, and fasteners, as well as ensuring proper grounding to minimize the risk of electrical faults or hazards.

Testing and Quality Assurance Procedures: After installation, it is important to perform thorough testing to verify the integrity of the installed armored cable system. This may involve conducting insulation resistance tests, continuity checks, or other relevant tests based on industry requirements.

Maintenance and Troubleshooting Tips

Regular Inspection and Preventive Maintenance: Regularly inspecting armored cable installations helps identify any signs of wear, damage, or degradation early on. This allows for timely preventive maintenance measures such as cleaning connections, tightening loose fittings, or replacing damaged components.

Identifying and Resolving Common Issues: Familiarizing oneself with common issues associated with armored cable systems can aid in troubleshooting efforts. These issues may include insulation breakdowns, loose connections, or environmental factors like rodent damage.

Repair and Replacement Guidelines: In cases where repairs or replacements are necessary due to damaged cables or faulty components, it is important to follow manufacturer guidelines and industry best practices. This ensures that repairs are done correctly while maintaining compliance with safety regulations.

By adhering to these best practices for installation and maintenance of armored cable systems, professionals can maximize their reliability while minimizing potential risks or disruptions.

Future Prospects of Armored Cable

The future of armored cable looks promising, driven by stainless steel innovations and ongoing advancements in cable technology. These developments are expected to further improve the durability and performance of armored cables, making them even more reliable for various applications. As technological breakthroughs continue to emerge, we can anticipate enhanced features and capabilities in armored cable systems. With their ability to withstand harsh environments, resist physical damage, and provide EMI shielding, armored cables will play a crucial role in industries such as construction, manufacturing, telecommunications, and power distribution. The continuous evolution of armored cable technology ensures that it remains a vital component in modern infrastructure projects and electrical systems.

See Also

Unveiling the Advantages of Outdoor Armored Cables

Analyzing the Potential of Fiber Optic Cables

The Advantages of IP68-rated Waterproof Fiber Optic Cables