Choosing the Right MPO Breakout Cable: A Comprehensive Comparison

Understanding MPO Breakout Cables

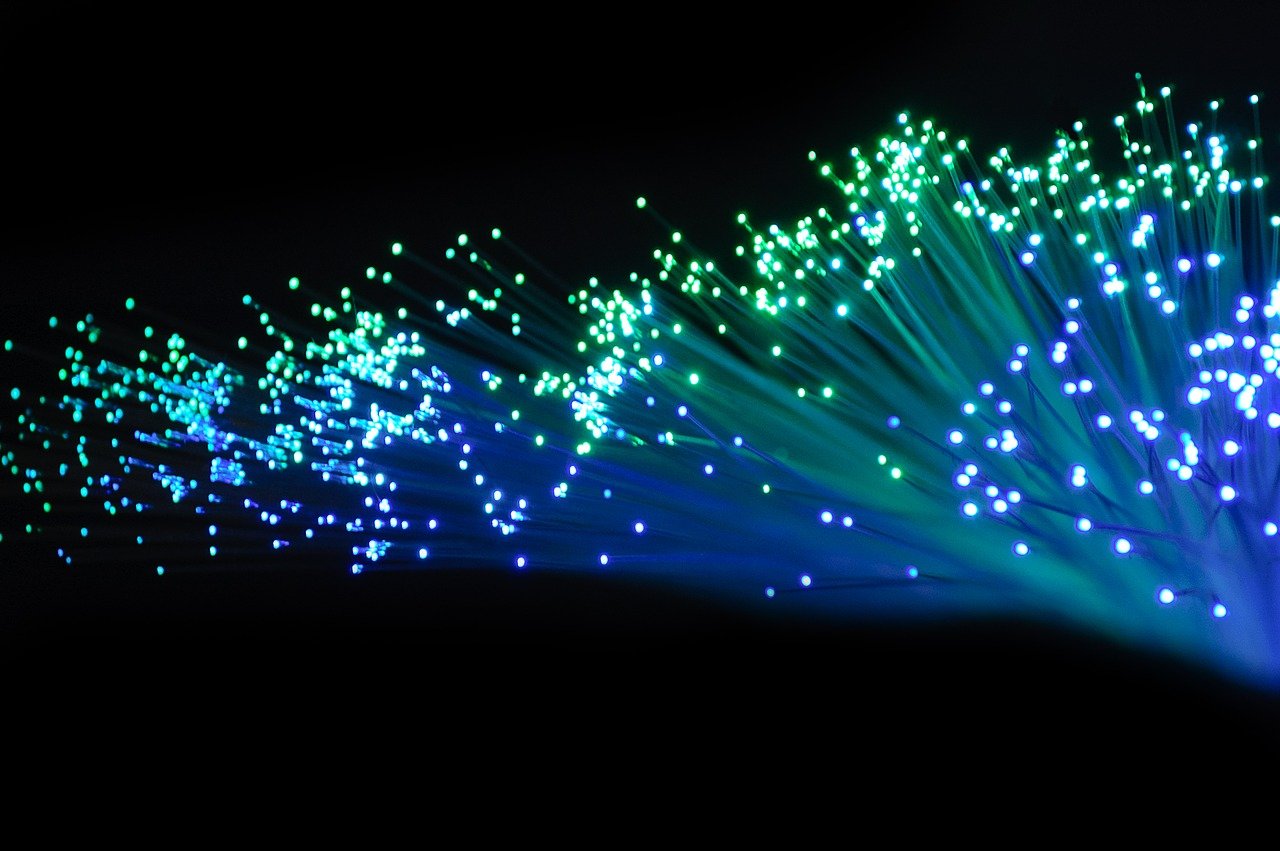

MPO breakout cables play a crucial role in network infrastructure, providing essential connectivity solutions for high-density fiber optic applications. These multi-fiber breakout cables are designed to split the signals from a single MPO connector into individual connectors, such as LC, SC, or ST. By doing so, they enable the connection of multiple devices to a single fiber optic link. Choosing the right MPO breakout cable is vital to ensure optimal performance and reliability in your network setup. Whether you need fiber optic breakout cables for data centers, telecommunications networks, or other high-speed applications, understanding their features and advantages is key to making informed decisions.

A Closer Look at MPO Breakout Cable Types

Understanding the different types of MPO breakout cables

MPO breakout cables come in various configurations to suit different network requirements. Some common types include:

MPO to LC breakout cables: These cables feature an MPO connector on one end and individual LC connectors on the other end. They are commonly used for connecting high-density fiber optic equipment to devices with LC interfaces.

MPO to MPO breakout cables: These cables have an MPO connector on both ends, allowing for direct connections between two MPO interfaces. They are often used for interconnecting fiber optic modules or patch panels.

MPO to SC breakout cables: These cables have an MPO connector on one end and individual SC connectors on the other end. They are suitable for connecting devices with SC interfaces to high-density fiber optic systems.

MPO to ST breakout cables: These cables feature an MPO connector on one end and individual ST connectors on the other end. They are commonly used for connecting devices with ST interfaces to multi-fiber breakout systems.

Comparing the features and advantages of each MPO breakout cable type

When choosing an MPO breakout cable, it's important to consider their performance characteristics, compatibility with different network equipment, and application scenarios.

Performance characteristics: Each type of MPO breakout cable may have specific performance attributes such as insertion loss, return loss, and bandwidth capabilities. Understanding these characteristics helps ensure optimal signal transmission in your network setup.

Compatibility with different network equipment: Different devices and equipment may require specific connector types. By selecting the right type of MPO breakout cable, you can ensure seamless compatibility between your network components.

Application scenarios: The choice of an appropriate MPO breakout cable depends on the specific application requirements. For example, if you need to connect a data center server rack to a patch panel, an MPO to LC breakout cable would be suitable. Understanding the application scenarios helps determine the most suitable option.

Key Factors to Consider when Choosing an MPO Breakout Cable

Performance requirements and specifications

When selecting an MPO breakout cable, several performance factors and specifications should be taken into account:

Bandwidth needs: Determine the required bandwidth for your network application. Higher bandwidth capabilities may be necessary for data-intensive applications like video streaming or cloud computing.

Transmission distance: Consider the distance over which the signal needs to be transmitted. Different MPO breakout cables have varying transmission capabilities, so choose one that meets your specific distance requirements.

Connector compatibility: Ensure that the connectors on the MPO breakout cable are compatible with the equipment you will be connecting. Verify if you need LC, SC, ST, or other types of connectors.

Environmental considerations

Environmental factors play a crucial role in determining the suitability of an MPO breakout cable for your installation:

Temperature range: Check the temperature range within which the MPO breakout cable can operate effectively. Extreme temperatures can affect signal transmission and overall performance.

Moisture and dust resistance: If you plan to install the MPO breakout cable in environments with high moisture levels or dust exposure, choose a cable that offers adequate protection against these elements.

Outdoor or indoor installation: Determine whether the MPO breakout cable will be installed indoors or outdoors. Outdoor cables require additional protection against UV radiation, water ingress, and physical damage.

Considering these performance requirements and environmental considerations ensures that you select an MPO breakout cable that meets your specific needs and provides reliable connectivity in your network infrastructure.

Best Practices for MPO Breakout Cable Installation and Maintenance

Proper handling and installation techniques

To ensure optimal performance and longevity of your MPO breakout cables, it is essential to follow these best practices during installation:

Cable routing and management: Properly route and manage the MPO breakout cables to minimize stress on the connectors. Use cable management solutions like trays, racks, or raceways to organize and protect the cables.

Connector cleaning and inspection: Before connecting the MPO breakout cables, ensure that the connectors are clean and free from dust or debris. Regularly inspect the connectors for any signs of damage or contamination.

Avoiding excessive bending or pulling: Handle the MPO breakout cables with care to avoid excessive bending or pulling, which can cause signal loss or damage to the cable structure. Use appropriate bend radius guidelines provided by the manufacturer.

Regular maintenance and troubleshooting

To maintain optimal performance of your MPO breakout cable setup, follow these maintenance practices:

Periodic inspections and cleaning: Regularly inspect the MPO breakout cables for any signs of wear, damage, or loose connections. Clean the connectors using lint-free wipes and approved cleaning solutions as per manufacturer recommendations.

Identifying and resolving connectivity issues: If you encounter connectivity issues in your network, troubleshoot by checking for loose connections, damaged components, or faulty equipment. Use appropriate testing tools to identify and resolve any issues promptly.

Replacing damaged or worn-out components: If you find any damaged or worn-out components during inspections, replace them immediately to prevent further degradation of signal quality. Follow proper procedures for component replacement as recommended by the manufacturer.

By adhering to these best practices for installation and maintenance, you can ensure reliable performance and longevity of your MPO breakout cable deployment.

Emerging Trends in MPO Breakout Cable Technology

Increased fiber density and higher transmission speeds

The field of MPO breakout cable technology is constantly evolving, with several emerging trends shaping the future of these cables:

Advancements in MPO connector technology: Manufacturers are continually improving MPO connectors to enhance their performance and reliability. These advancements include better alignment features, reduced insertion loss, and increased mating durability.

Support for higher data rates: As network demands continue to grow, MPO breakout cables are being designed to support higher data rates. This enables seamless transmission of large amounts of data, making them suitable for bandwidth-intensive applications.

Compatibility with emerging network standards: MPO breakout cables are being developed to meet the requirements of emerging network standards such as 40GBASE-SR4 and 100GBASE-SR10. These standards demand higher performance and greater bandwidth capabilities.

Integration of advanced features and functionalities

MPO breakout cables are also incorporating advanced features and functionalities to meet the evolving needs of network infrastructure:

Optical power monitoring: Some MPO breakout cables now come equipped with optical power monitoring capabilities. This allows for real-time monitoring of signal strength, ensuring optimal performance and facilitating proactive maintenance.

Polarity management: With the increasing complexity of multi-fiber connections, polarity management has become crucial. Advanced MPO breakout cables incorporate polarity management features that simplify installation and reduce errors in fiber optic systems.

Enhanced cable management systems: To improve organization and ease of use, newer MPO breakout cables feature enhanced cable management systems. These systems provide better cable routing options, strain relief mechanisms, and labeling solutions for efficient installation and maintenance.

As technology continues to advance, these emerging trends in MPO breakout cable technology will shape the future landscape by offering increased performance, compatibility with evolving standards, and enhanced functionality.

Analyzing Cost Factors and Industry Standards for MPO Breakout Cables

Cost comparison of different MPO breakout cable options

When considering MPO breakout cables, it's important to analyze various cost factors to make an informed decision:

Material quality and durability: Different MPO breakout cables may vary in terms of the materials used and their overall build quality. Higher-quality materials and construction can contribute to better performance and longevity, but they may come at a higher cost.

Manufacturing processes: The manufacturing processes involved in producing MPO breakout cables can impact their pricing. Cables manufactured using advanced techniques or with additional quality control measures may be priced higher due to the increased production costs.

Additional features and certifications: Some MPO breakout cables offer additional features such as bend-insensitive fibers, enhanced strain relief, or specialized certifications like fire resistance. These added features can affect the pricing of the cables.

Industry standards and compliance

Industry standards play a crucial role in ensuring the reliability and compatibility of MPO breakout cables:

TIA/EIA standards: The Telecommunications Industry Association (TIA) and Electronic Industries Alliance (EIA) have established standards that define the performance characteristics, testing methods, and requirements for MPO breakout cables. Compliance with these standards ensures interoperability between different network components.

ISO certifications: International Organization for Standardization (ISO) certifications provide further assurance of quality and adherence to global standards. ISO-certified MPO breakout cables meet specific criteria related to manufacturing processes, environmental management systems, or other relevant aspects.

RoHS compliance: Restriction of Hazardous Substances (RoHS) is a directive that restricts the use of certain hazardous substances in electrical and electronic equipment. RoHS-compliant MPO breakout cables are free from substances like lead, mercury, cadmium, and others that pose environmental or health risks.

Analyzing cost factors alongside industry standards helps you make a well-rounded decision when selecting an appropriate MPO breakout cable for your network infrastructure.

Making Informed Decisions with MPO Breakout Cables

Understanding the different types and features of MPO breakout cables is essential for making knowledgeable choices when it comes to your network infrastructure. By considering factors such as performance requirements, environmental conditions, and industry standards, you can ensure optimal performance and compatibility. Staying updated with emerging trends and advancements in MPO breakout cable technology helps in future-proofing your network setup. With this knowledge, you can make well-informed selections that meet your specific needs and enable seamless connectivity in high-density fiber optic applications.

See Also

A Comprehensive Guide to Selecting the Right LSZH Patch Cord

Quick and Stable Connections with Mini Fast Wire Cable-Connectors

A Revolutionary Solution: Unveiling the Power of FTTR Invisible Fiber Cable