The Power of ADSS Fiber Optic Dead End Kits in Cable Networks

Overview of ADSS Fiber Optic Dead End Kits

ADSS (All-Dielectric Self-Supporting) fiber optic dead end kits play a crucial role in ensuring the stability and reliability of cable networks. These kits are specifically designed to provide secure anchoring points for fiber optic cables, preventing them from sagging or breaking under tension. By utilizing all-dielectric materials, ADSS dead end kits eliminate the need for metal supports, making them ideal for areas with high electrical interference or corrosive environments.

The benefits of using ADSS fiber optic dead end kits in cable networks are numerous. Firstly, they offer exceptional strength and durability, allowing them to withstand extreme weather conditions such as strong winds and ice loads. Additionally, these kits are lightweight and easy to install, reducing both time and labor costs. Furthermore, their all-dielectric construction ensures that they do not interfere with the transmission of signals, resulting in improved network performance.

In the following sections, we will delve deeper into the installation process of ADSS fiber optic dead end kits, explore maintenance and troubleshooting tips, and discuss future advancements in this technology.

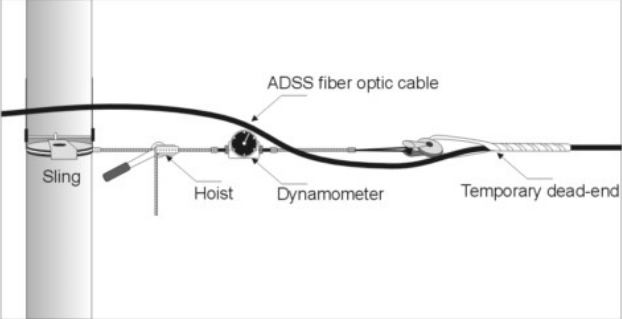

Installation Process of ADSS Fiber Optic Dead End Kits

Preparation for installation

Before installing ADSS fiber optic dead end kits, it is important to gather the necessary tools and equipment. This typically includes cable cutters, wrenches, suspension clamps, and any additional hardware specified by the manufacturer. It is also crucial to ensure that all safety measures are in place before beginning the installation process. This may involve wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses, and following proper electrical safety protocols.

Step-by-step installation guide

Identifying suitable locations for dead end kits: Start by assessing the cable network and determining where the dead end kits should be installed. Consider factors such as cable tension, span lengths, and clearance requirements. It is essential to follow the manufacturer's guidelines regarding spacing between dead end kits.

Attaching the kits securely to cable networks: Once suitable locations have been identified, proceed with attaching the dead end kits to the fiber optic cables. Begin by cleaning the cables thoroughly to remove any dirt or debris that could affect adhesion. Apply a suitable adhesive or bonding agent as recommended by the manufacturer, ensuring a secure bond between the kit and cable.

Securing suspension clamps: If suspension clamps are included with the dead end kit, install them at appropriate intervals along the cable span. These clamps provide additional support and help distribute tension evenly across the network.

Final inspection: After completing the installation process, perform a thorough inspection of all connections and attachments to ensure they are secure and properly aligned. Make any necessary adjustments or corrections as needed.

By following these step-by-step instructions, professionals in the telecommunications industry can effectively install ADSS fiber optic dead end kits in cable networks, ensuring optimal performance and reliability.

Maintenance and Troubleshooting Tips for ADSS Fiber Optic Dead End Kits

Regular maintenance practices

To ensure the optimal performance of ADSS fiber optic dead end kits, regular maintenance is essential. Here are some recommended practices:

Inspecting dead end kits for any signs of damage: Regularly check the condition of the dead end kits, including the hardware, clamps, and bonding agents. Look for any signs of wear, corrosion, or loose connections. If any damage is detected, it should be promptly repaired or replaced to prevent further issues.

Cleaning and maintaining the kits: Keep the dead end kits clean by removing dirt, dust, or other debris that may accumulate over time. Use a soft cloth or brush to gently clean the surfaces. Avoid using abrasive materials that could scratch or damage the kit components. Additionally, ensure that all bonding agents are intact and functioning properly.

Common troubleshooting techniques

Even with regular maintenance, issues may arise with ADSS fiber optic dead end kits. Here are some common troubleshooting techniques:

Identifying and resolving connectivity issues: If there are connectivity problems within the cable network, first check all connections between the dead end kits and cables. Ensure that they are securely attached and aligned correctly. If necessary, reposition or tighten any loose connections to restore proper signal transmission.

Addressing potential cable network disruptions: In case of disruptions in the cable network's performance, examine all components of the system, including the dead end kits. Look for any signs of physical damage or environmental factors that could be causing interruptions. Address these issues promptly to minimize downtime and maintain network reliability.

By following these maintenance practices and troubleshooting techniques, professionals can effectively keep ADSS fiber optic dead end kits in optimal condition and address any potential issues that may arise in cable networks.

Future Advancements in ADSS Technology

Emerging trends in ADSS fiber optic dead end kits

The field of ADSS technology is constantly evolving, with several emerging trends that are shaping the future of fiber optic dead end kits. Two notable trends include:

Integration of advanced monitoring and diagnostic capabilities: Future ADSS fiber optic dead end kits are expected to incorporate advanced monitoring systems that can provide real-time data on cable tension, temperature, and other key parameters. This enhanced monitoring capability will enable proactive maintenance and early detection of potential issues, allowing technicians to address them before they escalate into major problems.

Enhancements in durability and reliability: Manufacturers are continuously working on improving the durability and reliability of ADSS fiber optic dead end kits. This includes developing materials with increased resistance to environmental factors such as UV radiation, extreme temperatures, and moisture. By enhancing the robustness of these kits, they can withstand harsh conditions more effectively, resulting in longer service life and reduced maintenance requirements.

Potential impact on cable networks

The future advancements in ADSS technology are expected to have a significant impact on cable networks:

Improved network performance and efficiency: The integration of advanced monitoring capabilities will enable network operators to optimize performance by identifying potential bottlenecks or areas of concern. By proactively addressing these issues, network downtime can be minimized, leading to improved overall performance and customer satisfaction.

Reduced maintenance requirements: With enhanced durability and reliability, future ADSS fiber optic dead end kits will require less frequent maintenance interventions. This translates into cost savings for network operators as they can allocate resources more efficiently while ensuring reliable network operation.

As technology continues to advance, the power of ADSS fiber optic dead end kits will continue to grow, providing even greater benefits for professionals in the telecommunications industry. These advancements hold promise for improved network performance, increased efficiency, and reduced maintenance efforts in cable networks.

Conclusion: Harnessing the Potential of ADSS Fiber Optic Dead End Kits

In conclusion, ADSS fiber optic dead end kits offer numerous benefits in cable networks. Their all-dielectric construction provides exceptional strength and durability while ensuring optimal signal transmission. Proper installation, regular maintenance, and effective troubleshooting are essential for maximizing their performance and reliability.

Looking ahead, future advancements in ADSS technology hold promise for further improvements. The integration of advanced monitoring capabilities and enhancements in durability will contribute to improved network performance, increased efficiency, and reduced maintenance requirements.

By harnessing the potential of ADSS fiber optic dead end kits, professionals in the telecommunications industry can ensure the stability and reliability of cable networks, ultimately delivering high-quality connectivity to meet the growing demands of our digital world.

See Also

Harnessing the Potential of FastConnect: Features and Advantages

Robust and Dependable 2 in 1 Harden Optical Connector Cable Assemblies

Discovering the Advantages of IP67 Waterproof FTTX Solutions